As has been known for many years, the quality of the planting material is one of the biggest influences on future oil palm plantation yield. This is particularly true due to the long life cycle of the oil palm crop, which implies that bad planting material selection can affect yields for up to 25 years.

Essentially all modern planting materials obtained from a traditional seed production process (rather than by cloning) are based on DxP crosses. While these materials as a rule have very good yield results, stringent quality control is necessary during the seed production process to avoid contamination of flowers with unwanted pollen. To reconcile this strict quality control with the need to deliver large seed orders on time requires excellent planning and organization from seed production managers. OMP Seed Production is the specialized database application designed to help managers meet these challenges, and has been used successfully for several years by reputable seed producers.

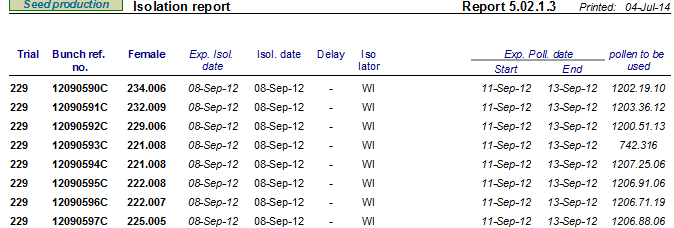

The starting point for the breeding process and the OMP Seed Production application is the collection of pollen from male trees and the isolation of female flowers in preparation for pollination. The program makes it easy to generate a time schedule for new isolations by entering an expected isolation date for each trial plot in the breeding program and each tree in the plot. For quality control purposes, initials of the worker responsible for the isolation of each individual bunch can be recorded. Similarly, pollen collection dates and amount of pollen collected can be recorded for each tree. At any stage, OMP Seed Production enables managers to view available pollen stocks and amounts of pollen that were already used or sold.

Flower isolation and pollen collection work schedules

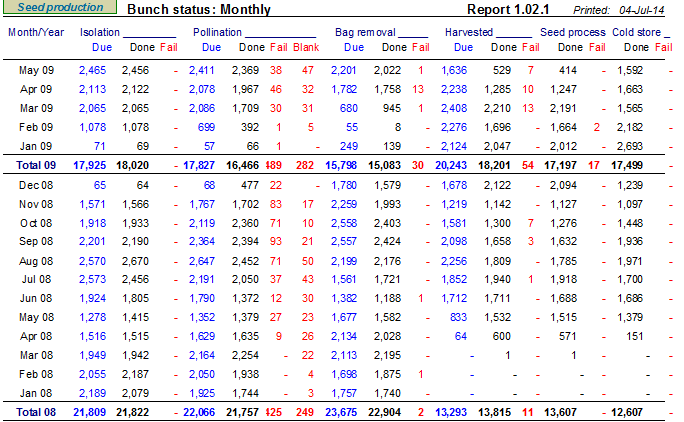

Based on the isolation dates, OMP Seed Production automatically predicts the optimal pollination time window. By entering the pollen to be used and the worker assigned to the job, managers can easily generate and monitor a pollination work schedule. Blank or failed pollinations can be recorded together with reasons for failure. Once a bunch has been pollinated, the program predicts dates for bag removal and harvesting. At each stage of the process, full details can be recorded including fail reasons and worker ID. The time interval between the individual steps to be used to predict pollination, bag removal and harvesting dates can be adjusted in the program’s system settings.

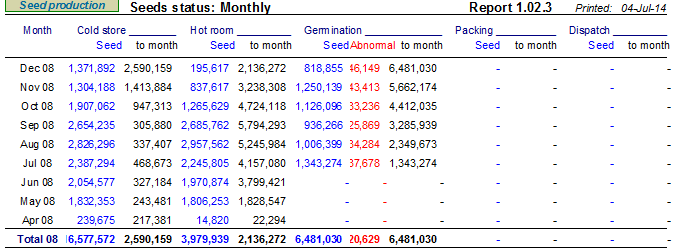

Seed stock monitoring

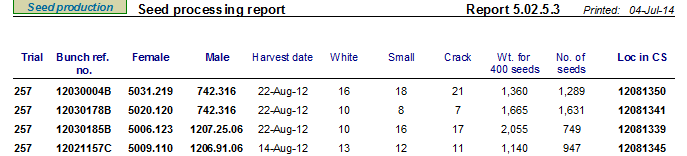

After harvesting, the number of seeds from each bunch is counted and any sub-standard seeds are recorded. OMP Seed Production allows you to keep full record of seed stocks in cold storage, including numbering and location in cold storage of individual seed bags and amounts of seeds in each bag. When seeds need to be dispatched to customers, they are moved from cold storage to a hot room to assist with germination. In addition to showing the full male and female lineage of all seeds in the hot room, OMP Seed Production predicts dates for when each seed batch is expected to start germinating. For each batch, 4 separate censuses for germinated seeds can be recorded in successive weeks. Finally, packing details of each set of germinated seeds is recorded in preparation for shipping to the customer.

Besides monitoring the actual production process as described above, OMP Seed Production also stores all the information on seed orders. This allows managers to easily review when seed shipments must be sent out and which proportion of ordered seeds has already been delivered. In combination with the data on seed stocks in cold storage or in the various stages of the germination process, this provides an excellent planning tool for seed production managers.

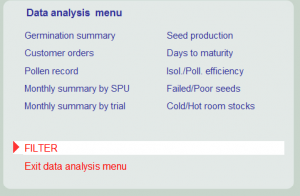

Data analysis features

Like all OMP programs, OMP Seed Production includes powerful filtering tools to narrow down the data you wish to view. All relevant information can be reviewed on monthly or daily basis using specialized data analysis forms and reports. Data analysis tools include topics such as days to maturity, isolator and pollinator efficiency, lists of failed bunches, seed order overviews and much more. Overall, OMP Seed Production provides a highly usable and fine-tuned instrument for seed production managers while providing full traceability of the lineage and processing history of each individual seed.